Progressive Stamping Die (H06)

- Productivity:

- 300sete/Year

- Place of Origin:

- Qingdao City,Shandong Province

- Supply Ability:

- 300sete/Year

Basic Info

Model No.: HRD-H06

Product Description

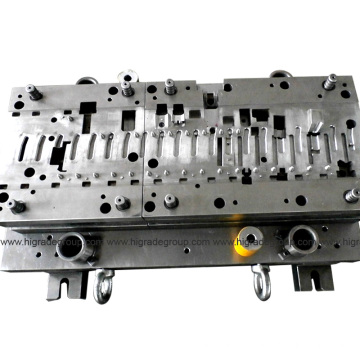

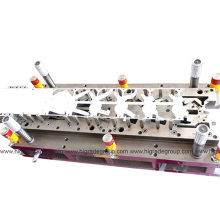

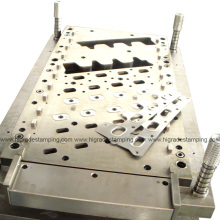

Model NO.: HRD-H06 Processing Method: Punching and Shearing Mould Process Combination: Progressive Die Driving Motor Type: Permanent Magnet Milling Speed: High Speed Place of Origin: Qingdao, China Mould Material: SKD11, Cr12MOV, P20+S Trademark: Higrade Origin: Qingdao City,Shandong Province Application: Household Appliances Technics: Forming Die Manufacturing Technology: Computer Technology Mold Cavity Technology: EDM Milling Parts Detection Method: Geometric Detection Certified: ISO9001: 2008 Standard Spare Parts: Festo Cylinder, Danly Spring System, Fabric Parts Specification: ISG9001: 2008 HS Code: 8480710090 Place of origin: Qingdao, China

1) We specialize in progressive die, progressive Stamping Die, metal Stamping part of progressive die. We had export some Progressive Dies to Japan, Italy, Iran, Germany.

2) The progressive die are related to home appliance, auto parts, electronic products, and so on.

3) ISO9001: 2008 certified by SGS.

4) Mould material: SKD11, Cr12MOV, P20+S, and so on.

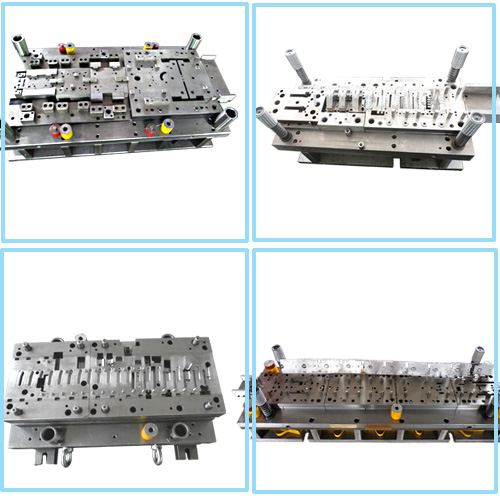

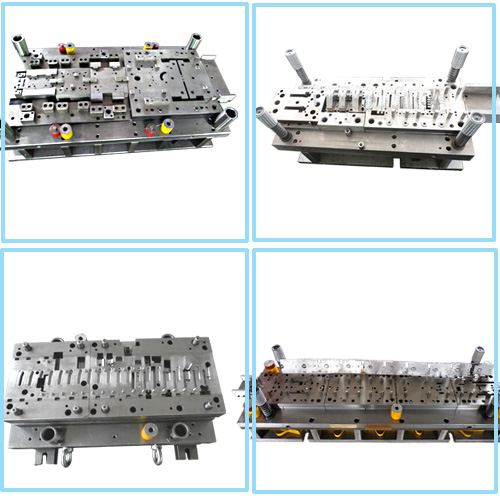

PROGRESSIVE DIE:

5) Standard spare parts: Festo cylinder, Danly spring system, Fabric parts

6) We accept the following file types of inquiry:

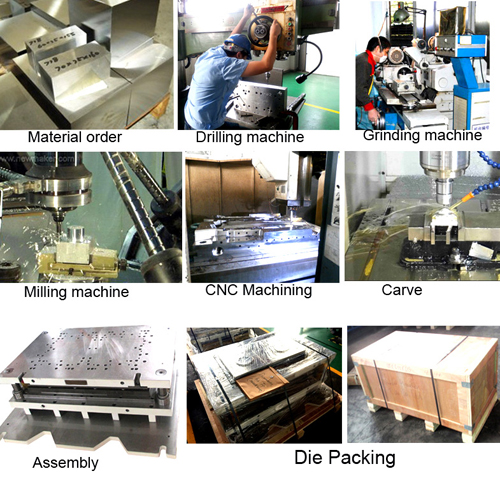

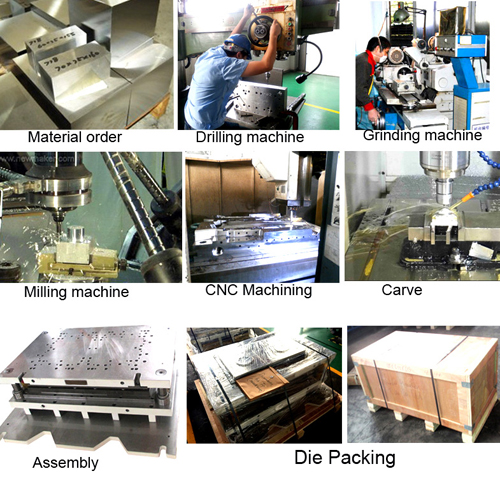

PRODUCTION PROCESS:

PRO/E Solidworks UG AutoCAD Adobe Acrobat

Dxf. Pdf. X_t. STP. Igs. Prt.

7)Packaging: Wooden case

Contact us if you need more details on Progressive Die. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Stamping Die、Progressive Punching Die. If these products fail to match your need, please contact us and we would like to provide relevant information.

1) We specialize in progressive die, progressive Stamping Die, metal Stamping part of progressive die. We had export some Progressive Dies to Japan, Italy, Iran, Germany.

2) The progressive die are related to home appliance, auto parts, electronic products, and so on.

3) ISO9001: 2008 certified by SGS.

4) Mould material: SKD11, Cr12MOV, P20+S, and so on.

PROGRESSIVE DIE:

5) Standard spare parts: Festo cylinder, Danly spring system, Fabric parts

6) We accept the following file types of inquiry:

PRODUCTION PROCESS:

PRO/E Solidworks UG AutoCAD Adobe Acrobat

Dxf. Pdf. X_t. STP. Igs. Prt.

7)Packaging: Wooden case

| Step | Item | Description |

| 1 | Quotation | We offer you the mould and part quotation according to your details--- Product drawings or Samples, with data of dimensions, product material, total quantity, weight. |

| 2 | Order | If our quotation is competitive and meet your mould requirements, you will place the order. |

| 3 | Drawing confirmation | We design the mould structure drawings according to your product drawing or sample. Feedback of drawings will be given for confirmation during the period. |

| 4 | Mould making | 1) After your confirmation of our drawing, we begin to make the moulds. |

| 2) During manufacturing program, we send you Mould Building Progress with pictures every week, for you to know our machining process. | ||

| 3) QC: We will conduct mould inspection in all the machining process to ensure the mould quality. | ||

| 5 | First trial | We will make the mould first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our mould quality according to sample. If you need to adjust the product structure, we can help you change the mould further. |

| 7 | Delivery | Ship the mould after it is completely OK, packed by wooden case. |

| 8 | After-sale service | We will contact you regularlyby professional persons and give our advice and solutions for mould use. |

Product Categories : Others Dies

Other Products

Hot Products

Hot Runner Mould&Injection Mould&Plastic Mould (C12)Vehicle Injection Mould / Auto Injection Molding (H70)Plastic Injection Mould/ Injection Plastic Mold (C8)Automatic Plastic Bottle Cap Molding MachtineMicrowave Oven Backpanel Parts&Microwave Oven Stamping Die (HRD-H39)Stamping Die/Metal Stampoing Tooling/Washing Machine Die (J03)Automatic Cap Compression Molding MachineSheet Metal Stamping/Progressive Stamping Metal Parts (J03)Pressing Automobile Metal Parts (HRD-H50)Stamping Die/Tooling/Metal Parts of Washing Machine (J03)Stamping Die/Toolingprogressive Tool (J03)Metal Deep Drawing Tool/ Drawn Metal Tooling of Washing Machine (J03)Stamping Die/Metal Stamping Tooling/Progressive Die (J03)Stamping Part (H03)Cap Automatic Progressive Molding MechanicalProgressive Stamping Tool for Motor Rotor Stator