Automatic Plastic Bottle Cap Molding Machtine

- Productivity:

- 110set/Year

- Place of Origin:

- Shenzhen

- Supply Ability:

- 110set/Year

Basic Info

Model No.: 1881 2925 3025 38act

Product Description

Model NO.: 1881 2925 3025 38act

Type: Plastric Madeing Machine

Logo Printing: With Logo Printing

Flexibility: Soft

Name: Automatic Plastic Bottle Cap Molding Machtine

Trademark: Multin

Specification: PE/PP

HS Code: 3923900000

Material: Plastic

Application: Plastic Bottle Caps

Recycled: Unrecycled

Technics: Bottle Blowing

Company Name: Shenzhen Multwin Technology Co,.Ltd.

Transport Package: Woods Box

Origin: Shenzhen

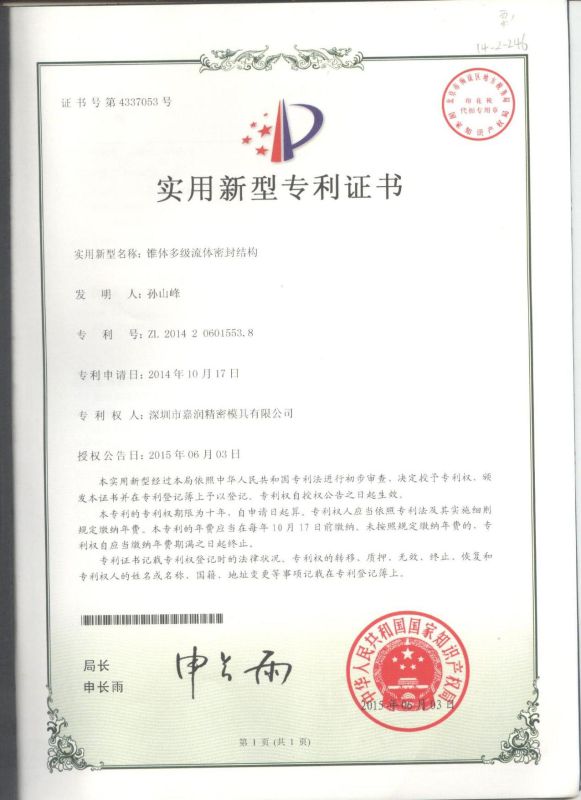

Shenzhen Jiarun Precision Science&Technology Co,.Ltd located in Songgang town,Bao' an district ,shenzhen City,Chain.Founded in 1997.which is a modern high-tech enterprise with integration of scientific research and development and manufacturing.

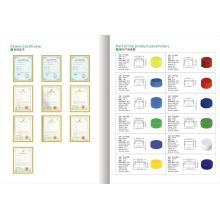

Jiarun Science&Technology Co.,Ltd is the first Company that passed ISO9001 qualiy managment system certification in Automatic plastic bottle cap molding machine Industry;We are a factory specializd production Mould and Full-Automatic compression plastic Bottle Cap Machine.

We research and development major production MTW-16,MTW-24,MTW-32,MTW-36,MTW-48

etc high quality compression plastic bottle cap machine.,and a variety of Matching mould for Mineral water,beverage,medical treatment bottle cap,like 1881,2925,3025,38and so on.

We have a hard work and positive research and development,manufacturing and sales team,having our own core technology and have 20 years rich experience in high processing and manufacturing.Our company taking the customers as the center,Quality as the fundamental, Continuous improvement is our purpose,at the same time,provide good pre-market and after-sales services, Based on Domestic customers and developmenrt of Southeat-Asia and other countries in the would.

| Type | Raw material | Number of mold cavity | Maximum prodution capacity | Cap Height |

| MTW-16 | PP/PE | 16 | 12000-14000(Φ30MM) | 10-25mm |

| Cap Diameter | Actual power | Voltage | Compressed air (self-provide) | weight | Dimensions(LWH) |

| Φ26-Φ38 | 45Kw | 220V 60Hz/380V 50Hz | 0.8Mpa 1.50m³ | 3.5T | 3000*1500*2100mm |

| Type | Raw material | Number of mold cavity | Maximum prodution capacity | Cap Height |

| MTW-24 | PP/PE | 24 | 17000-21000(Φ30MM) | 10-25mm |

| Cap Diameter | Actual power | Voltage | Compressed air (self-provide) | weight | Dimensions(LWH) |

| Φ26-Φ38 | 35Kw | 220V 60Hz/380V 50Hz | 0.8Mpa 1.50m³ | 4.5T | 3500*1700*2100mm |

| Type | Raw material | Number of mold cavity | Maximum prodution capacity | Cap Diameter |

| MTW-32 | PP/PE | 32 | 23000-28000(Φ30MM) | Φ26-Φ38 |

| Actual power | Voltage | Compressed air (self-provide) | weight | Dimensions(LWH) |

| 45Kw | 220V 60Hz/380V 50Hz | 0.8Mpa 2.0m³ | 6T | 4500*1900*2200mm |

| Type | Raw material | Number of mold cavity | maximum production capacity | Cap Diameter | Cap Height |

| MTW-48 | PP/PE | 48 | 31000-40000(ø30mm) | ø26-ø38 | 10-25mm |

| Actual power | Voltage | compressed air (self-provide) | weight | Dimendions(LWH) |

| 55KW | 220V 60Hz/380V 50Hz | 1.0Mpa 3.0m³ | 6.5T | 5500x1900x2200mm |

| Type | Raw material | Number of mold cavity | maximum production capacity | Cap Diameter | Cap Height |

| MTW-64 | PP/PE | 64 | 42000-60000(ø30mm) | ø26-ø38 | 10-25mm |

| Actual power | Voltage | compressed air (self-provide) | weight | Dimendions(LWH) |

| 70KW | 220V 60Hz/380V 50Hz | 1.0Mpa 3.0m³ | 7T | 6500x2000x2200mm |

Advantages:

1.high Efficiency.

Using the successive cyclic operation,compared with the traditional Injection Molding Machine ,the same power output increases more than 3 times.

2.Energy conservation.the main energy of plastic material is from the extrusion screw and mechanical friction material ,not the electric heating unit from a plasticizing screw ,to reduce electricity so as to achieve the effect of saving energy.

3.Quality stability.The use of hydraulic

pump for power transmission,rapid and stable,force large and uniform,to produce a more stable product size.

4.Low loss.No injection molding ,

Compression molding produce feed point there is no hot runner waste,to improve the utilization ration of raw materials by 98%.

5.Flexible manpower line:simple

Operation,and bottle cap check in line,Cap Compression Molding Machine connect with others equipment to be a production line,can save labor cost.

Contact us if you need more details on Plastic Bottle Cap. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Bottle Capping Machine、Bottle Equipment. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Bottle Caps

Premium Related Products

Other Products

Hot Products

Hot Runner Mould&Injection Mould&Plastic Mould (C12)Vehicle Injection Mould / Auto Injection Molding (H70)Plastic Injection Mould/ Injection Plastic Mold (C8)Automatic Plastic Bottle Cap Molding MachtineMicrowave Oven Backpanel Parts&Microwave Oven Stamping Die (HRD-H39)Stamping Die/Metal Stampoing Tooling/Washing Machine Die (J03)Automatic Cap Compression Molding MachineSheet Metal Stamping/Progressive Stamping Metal Parts (J03)Pressing Automobile Metal Parts (HRD-H50)Stamping Die/Tooling/Metal Parts of Washing Machine (J03)Stamping Die/Toolingprogressive Tool (J03)Metal Deep Drawing Tool/ Drawn Metal Tooling of Washing Machine (J03)Stamping Die/Metal Stamping Tooling/Progressive Die (J03)Stamping Part (H03)Cap Automatic Progressive Molding MechanicalProgressive Stamping Tool for Motor Rotor Stator