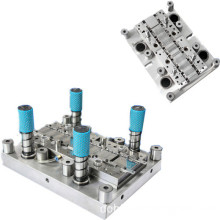

Progressive Die for Reluctance Motor Stator and Rotor

- Productivity:

- 500/Year

- Place of Origin:

- China

- Supply Ability:

- 500/Year

Basic Info

Model No.: progressive tool

Product Description

Model NO.: progressive tool Material: Mould Steel Technics: Cutting Die Manufacturing Technology: Automation Technology Mold Cavity Technology: CNC Milling Parts Detection Method: Measurement of Three Axis NC Type: Progressive Die Accuracy: 0.002mm Product: Rotor Stator Trademark: jiarun precision Origin: China Application: Motor Processing Method: Punching and Shearing Mould Process Combination: Progressive Die Driving Motor Type: Air Cylinder Milling Speed: Normal Speed Name: Progressive Die for Motor Rotor Stator Lamination Raw Material: Mould Steel Speed: 250-400/Min Function: Motor Power Specification: iso9001 HS Code: 8207300090 Specifications

progressive die for reluctance motor stator and rotor

ISO9001;2008

19 years experience

Japan high tech

auto interlocked Stamping Die for reluctance motor stator and rotor

Incorporated in the year 1997,we are a vertically integrated company which has been proficiently engaged in production & export of:-

Motor stator and rotor Stampings

We can manufacture laminations in all grades of electrical steel including fully or semi processed steel in the form of Stators & Rotors, Field & Armatures in loose as well as Interlocked & Auto Skewed Cores, AC/DC motor stator and rotor , induction motor stator ,brushless motor stator and rotor , stepper motor stator and rotor ,SR motor stator and rotor ,PM motor stator and rotor,universinal motor stator and rotor, etc

Die Stamping

We have in house Pressure Die stamping Facilities for the process of stamping stator and rotor.

Tool Room:-

We have a fully equipped tool room for support of the Press shop & Die stamping Shop.

Our precision engineered products and advanced manufacturing practices gives us a cutting edge over our competitors.

Progressive stamping die for motor stator rotor lamination technology

QUALITY:tolerance of spare part is within 0.002mm , tolerance of feeding length is within 0.003-0.005mm , and groundness is within R0.05-0.5,

STATOR ROTOR Technology : stator rotor tolerance is within 0.05mm , concentricity is within 0.05mm ,

SPEED: stamping speed reach 350-400 strokes per minute .

Life: regarding life reaches 1 million to 5 million strokes , while total life from 100million to 200 million ,

Product size : we make stamping die for motor stator rotor from od 3mm to 1000mm ,

Technology: 1.auto interlocking

2. skewing

3.shoulder hole for stator rotor lamination

4.rotation for lamination within 180 degree .

Mould material: tungsten steel ,SKD11 , SAP-60, ASP-9 etc .

Quality Certified

In order to offer our worldwide clients quality cost-effective precision metal stamping services JR is ISO 9001:2008 registered and carefully follows those standards. Our JR tool and die professionals, each with over 14 years of experience in building and maintaining complex metal stamping dies, keep up with the latest technologies by participating in continuous education in metal stamping manufacturing methodologies. To meet all of our customer needs,JR offers these combined capabilities in our state-of-the-art 3600 square meter facility:

Product design and prototyping using the latest solid modeling

Building of progressive metal stamping dies and tooling

General machining requirements like CNC Wire EDM and CNC Milling.

Secondary operations- welding, tapping, assembly, plating, painting and tumbling

Warehouse, Just-In-Time delivery

Let us show you how we expertly provide our cost-effective precision metal stamping services in a timely manner. We pride ourselves in our proven track record of professionally producing and assurance checking all our finished metal design products.

Contact us if you need more details on Progressive Tooling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Motor Rotor Stator、Stamping Lamination Sheet. If these products fail to match your need, please contact us and we would like to provide relevant information.

progressive die for reluctance motor stator and rotor

ISO9001;2008

19 years experience

Japan high tech

auto interlocked Stamping Die for reluctance motor stator and rotor

Incorporated in the year 1997,we are a vertically integrated company which has been proficiently engaged in production & export of:-

Motor stator and rotor Stampings

We can manufacture laminations in all grades of electrical steel including fully or semi processed steel in the form of Stators & Rotors, Field & Armatures in loose as well as Interlocked & Auto Skewed Cores, AC/DC motor stator and rotor , induction motor stator ,brushless motor stator and rotor , stepper motor stator and rotor ,SR motor stator and rotor ,PM motor stator and rotor,universinal motor stator and rotor, etc

Die Stamping

We have in house Pressure Die stamping Facilities for the process of stamping stator and rotor.

Tool Room:-

We have a fully equipped tool room for support of the Press shop & Die stamping Shop.

Our precision engineered products and advanced manufacturing practices gives us a cutting edge over our competitors.

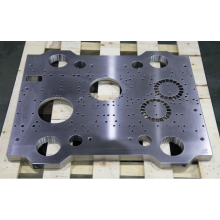

| Product Name | reluctance motor stator and rotor |

| Die steel | AISI D2/JIS SKD11/ Din1.2379, ASP-23, SKH-9,ASP60,CARBIDE,etc |

| Stamping Material Type | Carbon steel, hot-dipped galvanized steel, SECC, stainless steel, aluminum, brass, copper, plastic, rubber, FPC(flexible printed circuit) etc. |

| Stamping Material Thickness | 0.1mm-12mm |

| Precision | Tolerance +/- 0.02~0.05 mm |

| Lead time | Depending on individual products. Normally from 35 to 60 days for T1 sample |

| Quality Assurance | ISO9001;2008 certificated factory, |

| Surface Finish | electroplating, Powder coating, Conversion, Passivation , Anodize, Alodine, Electrophoresis, etc. |

| Measuring Instruments | 3D CMM, Hardness Meter, Projector, Digital Height , Microscope ,etc. |

| Equipment | CNC Machining Center, Sodick EDM, Fine Precision Grinding Machine , 20T to 220T Press Machines, etc. |

| Design Software | PRO/E, Auto CAD, Solid Work , UG , Master CAM, Auto form |

| Applications | Automotive (chassis system, seating and door system, audio systems , cooling system); Home Appliances (TV sets, cameras, air conditioners ,DVD players); Telecommunication (Antenna base, brackets, enclosures ); Fire-fighting equipment (holding plates); In-office equipments like computers, copiers and printers, etc |

QUALITY:tolerance of spare part is within 0.002mm , tolerance of feeding length is within 0.003-0.005mm , and groundness is within R0.05-0.5,

STATOR ROTOR Technology : stator rotor tolerance is within 0.05mm , concentricity is within 0.05mm ,

SPEED: stamping speed reach 350-400 strokes per minute .

Life: regarding life reaches 1 million to 5 million strokes , while total life from 100million to 200 million ,

Product size : we make stamping die for motor stator rotor from od 3mm to 1000mm ,

Technology: 1.auto interlocking

2. skewing

3.shoulder hole for stator rotor lamination

4.rotation for lamination within 180 degree .

Mould material: tungsten steel ,SKD11 , SAP-60, ASP-9 etc .

| Item | Description |

| Description | High speed stamping tool for motor lamination |

| Type | Progressive stamping die , compound die, single die |

| Material | SKD11, D2, SKH51, SKD61, Cr12MoV ,etc |

| Work piece Material | Alloy steel: SKD11, SKD61, Cr12MOV, SLD, DC53 High speed steel:SKH51, SKH9, YXM1 |

| Stations / Steps | According to the auto parts designing |

| Productions Cover | Sheet metal auto parts, Auto stamping parts, Home Electrics stampingparts, Device stamping parts, etc |

| Productivity | Max 400 pcs/min, normally 40-60pcs/min |

| Work piece Precision: | 0.005mm |

| Mould Tolerance | 0.001-0.003 mm |

| Life Time | Max 1 million times, normally 0.3-0.5million times |

| Design Software | AutoCAD, PRO/E, Solid works, UG(NX), Cimatron, MasterCAM |

| Drawing Format | STP, PRT, ASM, PDF, DWG, DXF,JPG,TIFF,PNG |

| Surface Treatment | Powder coating, Hot galvanized, Painting, Polishing, Brushing ,Chrome/Zinc/Nickel plating |

| Certification | ISO9001:2008 |

| Service | OEM / ODM service |

| Machinery Equipments | Milling, Grinding, Boring, CNC, EDM, WEDM, Forming Machine,Precision flat milling, Saw machine, Punching Machine |

| Testing Machine | 100% Inspection, CMM, Projector, Microscope |

| Supplying Report | Material reports and Dimension test reports made from the originof the place |

| Payment Terms | T/T, L/C , West Union ,etc |

| Advantage | We are experienced in the mould design and process through ourcooperation with Japanese and USA companies in the past years.We had built our own factory in Shenzhen and established long-term,and stable business relationships with other factories. |

| Business Scope & Service Details | All products can be customized according to different Nationalstandards and customer needs. As a trading & manufacturingcompany, JR is also involving in OEM & ODM outsourcingand collaboration, bespoke manufacturing of blue drawing,sample, raw material and originality products. We can provideclients with product design, competitive pricing, qualityassurance that fulfill their needs and logistics services. |

| Standard | JIS AISI DIN etc. |

Quality Certified

In order to offer our worldwide clients quality cost-effective precision metal stamping services JR is ISO 9001:2008 registered and carefully follows those standards. Our JR tool and die professionals, each with over 14 years of experience in building and maintaining complex metal stamping dies, keep up with the latest technologies by participating in continuous education in metal stamping manufacturing methodologies. To meet all of our customer needs,JR offers these combined capabilities in our state-of-the-art 3600 square meter facility:

Product design and prototyping using the latest solid modeling

Building of progressive metal stamping dies and tooling

General machining requirements like CNC Wire EDM and CNC Milling.

Secondary operations- welding, tapping, assembly, plating, painting and tumbling

Warehouse, Just-In-Time delivery

Let us show you how we expertly provide our cost-effective precision metal stamping services in a timely manner. We pride ourselves in our proven track record of professionally producing and assurance checking all our finished metal design products.

| Shenzhen Jiarun Precision Industry Co., Ltd | |

| Founded time | 1997 |

| Registered Place | Shenzhen |

| Management Mode | Production and serving model |

| Whether offer OEM | Yes |

| Factory Area | 3000m2 |

| Main Market | Every city of China, Southeast Asia, South America, Brazil, India |

| Main customer | Foreign, institutions in China ,Foreign enterprises , |

| Company's licence | Business License for Legal Person, ISO9001:2008 by SGS |

| Company's address | Building No.2,North, Yanchuan north Industry district, Songgang Town, |

| Phone | 86-0755-23491191 86-0755-23490155 |

| Fax | 86-0755-23490062 |

| Company Introduction | We are professional with progressive die, stamping die. Tooling material is good quality. We could provide service all about precision sheet metal stamping dies including stamping die design, stamping die manufacturing, machining and trouble shooting of stamping dies. |

| Main Products | motor rotor and stator , motor bracket, shredder blade,Computer, mobile phone connector terminals, motor core stamping mould. |

| Main Service | According to the customer's drawings for mould design ,development and manufacture. |

| Other Features | 1.In-time response on letters, telephone calls or fax 2.In-time supply the quotation and mould designs 3.In-time communication on the technical points 4.In-time sending pictures for the mould machining progress and mould finishing schedule 5.In-time mould delivery |

| Quote | According to sample, drawing and specific requirement. |

| ↓ | |

| 2. Discussion | Mold material, cavity number, price, runner, payment, etc. |

| ↓ | |

| 3. S/C Signature | Approval for all the items |

| ↓ | |

| 4. Design mold | We will send mold design to customer for confirmation |

| ↓ | |

| 5. Mold tooling | We start to make mold after mold design confirmed |

| ↓ | |

| 6. Mold processing | Send report to customer once each week |

| ↓ | |

| 7. Mold Testing | Send trial samples and try-out report to customer for confirmation |

| ↓ | |

| 8. Mold Modification | According to customer' s feedback |

| ↓ | |

| 9. Delivery | Ship mold(3D & 2D drawing in DVD, manual) after try-out sample confirmed |

Product Categories : Stamping Die

Premium Related Products

Other Products

Hot Products

Hot Runner Mould&Injection Mould&Plastic Mould (C12)Vehicle Injection Mould / Auto Injection Molding (H70)Plastic Injection Mould/ Injection Plastic Mold (C8)Automatic Plastic Bottle Cap Molding MachtineMicrowave Oven Backpanel Parts&Microwave Oven Stamping Die (HRD-H39)Stamping Die/Metal Stampoing Tooling/Washing Machine Die (J03)Automatic Cap Compression Molding MachineSheet Metal Stamping/Progressive Stamping Metal Parts (J03)Pressing Automobile Metal Parts (HRD-H50)Stamping Die/Tooling/Metal Parts of Washing Machine (J03)Stamping Die/Toolingprogressive Tool (J03)Metal Deep Drawing Tool/ Drawn Metal Tooling of Washing Machine (J03)Stamping Die/Metal Stamping Tooling/Progressive Die (J03)Stamping Part (H03)Cap Automatic Progressive Molding MechanicalProgressive Stamping Tool for Motor Rotor Stator