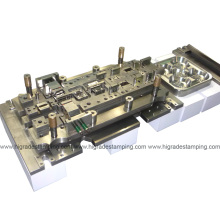

Stamping Progressive Part/ Progressive Stamped Tool (H82)

- Productivity:

- 400 Sets/Year

- Place of Origin:

- China

- Supply Ability:

- 400 Sets/Year

Basic Info

Model No.: EO23

Product Description

Model NO.: EO23 Processing Type: Shaping Metal Mould: Multistep Progressive Dies Process: Forming Process Tolerances: 0.02mm Stamping Die Life: 50000~500000shots; Scope of Application: Automotive Processing Date: 35~45 Days Transport Package: Wooden Case Origin: China Type: Cold Stamping Material: Stainless Steel Fine Blanking: Open Industry: Metal Stamping Parts Customized: Customized Product Material: SUS304,SPCC Certificate: ISO9001:2008 Trademark: Higrade Specification: ISO9001: 2008 HS Code: 8480710090 {Product material}: SUS304, SPCC and so on

{Scope of application}: Automotive die

{Die types}: Progressive Die

{Mould Life}: 50~100 shots

{Tolerances}: 0.02mm

{Processing Date}: 35~45 days

{Spare parts}: PUNCH, MISUMI and so on

{Equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T\200T\160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, Sanyo, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements

(Packaging: Wooden case)

Company introduction:

Higrade Group is established on 2003, which is covered an area of 60 acres. We are mainly managing injection mould, stamping die, plastic parts and stamping parts. Our manufacture equipment include Hexagon(Swiss) CMM, Mazak CNC, Sodic EDM, Sodic W-cutting, Depth drill, Carving and so on, and we build many production line for plastic and metal parts. Higrade always pursue high quality with lower cost.

The Injection Moulds are involved in home appliances, automotive, electronic, medical and other fields. Our mainly customers include Haier, Hisense, Midea, SIEMENS, SANYO, Electrolux, FOTON, GM, WULING etc. We could make different sizes mouls and gain great reputation.

We are specialized in plastic parts from 2011 with home appliance, automotive, electric and etc. Due to our good quality and service, we earn more and more customers, and get long-term cooperation with SIEMENS, HYUNDAI, KIA, and DAMSUNG etc. Our injection machine is 86-160T, 180T, 250T, 380T, 520T, 750T, 1300T and one vertical injection machine; We can test and produce with all sizes of injection mould. To meet the customer request and achieve to production quickly, we assemble the robot in injection machines.

For the metal dies, we are mainly specialized in progressive die, drawing die and compound die. We export to more than 30 countries as Europe, North America, Japan, Thailand, Russia, and South Africa and so on; So we have much export experience. In addition, now we owned the 315T hydraulic press, and many pressess as 200T/160T/110T/80T/40T, they can meet the request of test and batch production.

We obtain the ISO9001: 2008 quality system certificate by SGS from 2007. We build complete organization including top management, marking department, project management, purchase department, engineer department, production department, and logistic department.

Contact us if you need more details on Stamping Die/Tooling. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Progressive Stamped Tooling、Metal Progressive Stamping Die. If these products fail to match your need, please contact us and we would like to provide relevant information.

{Scope of application}: Automotive die

{Die types}: Progressive Die

{Mould Life}: 50~100 shots

{Tolerances}: 0.02mm

{Processing Date}: 35~45 days

{Spare parts}: PUNCH, MISUMI and so on

{Equipment}: 400T Punch

{Produce equipment}: 315T Hydraulic machine/press, 400T\200T\160T Punch (With the belt feeding machine), 110T, 80T, 40T Punch equipment, Can meet the need of mass production and testing.

{Service content}: Designing and manufacturing for metal mould and products.

{Main customers}: Haier, Hisense, Midea, Siemens, Sanyo, Electrolux, Toyota, KIA, Foton, SGMW, SKYWORTH etc.

{Main export markets}: Japan, Korea, Thailand, Russia, Germany, Britain, Norway, Italy, Spain, Turkey; America, Brazil, Argentina; South Africa Egypt; Iran, Pakistan, India etc...

{Mold paint}: Painting color depends on customer requirements

(Packaging: Wooden case)

Company introduction:

Higrade Group is established on 2003, which is covered an area of 60 acres. We are mainly managing injection mould, stamping die, plastic parts and stamping parts. Our manufacture equipment include Hexagon(Swiss) CMM, Mazak CNC, Sodic EDM, Sodic W-cutting, Depth drill, Carving and so on, and we build many production line for plastic and metal parts. Higrade always pursue high quality with lower cost.

The Injection Moulds are involved in home appliances, automotive, electronic, medical and other fields. Our mainly customers include Haier, Hisense, Midea, SIEMENS, SANYO, Electrolux, FOTON, GM, WULING etc. We could make different sizes mouls and gain great reputation.

We are specialized in plastic parts from 2011 with home appliance, automotive, electric and etc. Due to our good quality and service, we earn more and more customers, and get long-term cooperation with SIEMENS, HYUNDAI, KIA, and DAMSUNG etc. Our injection machine is 86-160T, 180T, 250T, 380T, 520T, 750T, 1300T and one vertical injection machine; We can test and produce with all sizes of injection mould. To meet the customer request and achieve to production quickly, we assemble the robot in injection machines.

For the metal dies, we are mainly specialized in progressive die, drawing die and compound die. We export to more than 30 countries as Europe, North America, Japan, Thailand, Russia, and South Africa and so on; So we have much export experience. In addition, now we owned the 315T hydraulic press, and many pressess as 200T/160T/110T/80T/40T, they can meet the request of test and batch production.

We obtain the ISO9001: 2008 quality system certificate by SGS from 2007. We build complete organization including top management, marking department, project management, purchase department, engineer department, production department, and logistic department.

| Step | Item | Description |

| 1 | Quotation | We offer you the mould and part quotation according to your details(drawing or sample, material, quantity, weight). |

| 2 | Order | If our quotation is competitive, you will place the order. |

| 3 | Drawing design | We design the mould structure drawing according to your product drawing or sample, then send to you for confirmation. |

| 4 | Mould making | After your confirmation of our drawing, we begin to make the moulds, during manufacturing program, we send you mould building progress with pictures every week, for you to know our process. |

| 5 | First trial | We will make the mould first trial on time, then send you video, picture and samples for you to confirm. |

| 6 | Quality confirm | You will confirm our mould quality according to sample. If you need to adjust the product structure, we can help you change the mould further. |

| 7 | Delivery | Ship the mould after it is completely OK, packed by wooden case. |

Product Categories : Progressive Dies

Other Products

Hot Products

Hot Runner Mould&Injection Mould&Plastic Mould (C12)Vehicle Injection Mould / Auto Injection Molding (H70)Plastic Injection Mould/ Injection Plastic Mold (C8)Automatic Plastic Bottle Cap Molding MachtineMicrowave Oven Backpanel Parts&Microwave Oven Stamping Die (HRD-H39)Stamping Die/Metal Stampoing Tooling/Washing Machine Die (J03)Automatic Cap Compression Molding MachineSheet Metal Stamping/Progressive Stamping Metal Parts (J03)Pressing Automobile Metal Parts (HRD-H50)Stamping Die/Tooling/Metal Parts of Washing Machine (J03)Stamping Die/Toolingprogressive Tool (J03)Metal Deep Drawing Tool/ Drawn Metal Tooling of Washing Machine (J03)Stamping Die/Metal Stamping Tooling/Progressive Die (J03)Stamping Part (H03)Cap Automatic Progressive Molding MechanicalProgressive Stamping Tool for Motor Rotor Stator