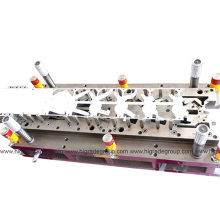

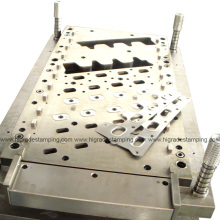

Plastic Mould/Injection Molding/Washing Machine Cover Injection Mold

- Productivity:

- 10000

- Place of Origin:

- China Qingdao

- Supply Ability:

- 10000

- Certificate:

- ISO

Basic Info

Model No.: HRD-Z175

Product Description

Model NO.: HRD-Z175 Surface Finish Process: Polishing Plastic Material: ABS Application: Household Appliances Design Software: UG Certification: ISO Customized: Customized Mould Material: 2738, Nak80, 718, 738h, 2344, S136, SKD11 Certified: ISO9001: 2008 Specification: ISO9001: 2008 HS Code: 8480710090 Shaping Mode: Injection Mould Mould Cavity: Single Cavity Process Combination Type: Single-Process Mode Runner: Hot Runner Installation: Fixed Standard: HASCO Mould Base: Lkm, Hasco, Stiehl Cavity: Single/Multiple Trademark: Higrade Mould Origin: China Qingdao Mould Steel: 2738HH, NAK80, 738, 2344, S136, SDK61, P20, PX5 etc.

Mould Life: 50~100 shots

Material: ABS

Cavity: 1*1

Applicable range: Home appliance

Lead Time: 35-45 days

Hot runner: (according to the customer's request and product style)

Standard part: PUNCH, MISUMI

First trial equipment: 380T Injection Machine( moreover we also have 90-700T, 750-1300T Injection Machine. There are robots for each 90-380T Injection Machine to meet the customer's bulk production requirement.

Process step: Product design- CAE- 3D mold design- 2D drawing- CAM- Milling machine- Grinder- Drill- CNC- Wire cutting- EDM- Polishing- Trial assembly- Grind- Assemble- First trial

Our service: Product and mould design, Injection mould and parts machining.

Our main customer: Haier, Hisense, Midea, Siemens, SANYO, ELX, Toyota, Kia, Foton, GM Wuling, Great wall, Hyundai, Skyworth.

Overseas market: Japan, Korea, Thailand, Russia, Germany, England, Norway, Italy, USA, Spain, Turkey, Denmark, Brazil, Argentina, Egypt, South Africa, Iran, Pakistan, India.

Mould painting: According to Customer's request

Package: Wooden Case

The first trial success rate is above 95%

Quotation: Provide quotation in 24hours after received the customer's drawing.

The profile: 2D/3D drawing or samples

Manager: Concentrate on project tracking and after service

Engineer: 30-50 excellent engineers, have many years experience and English communicating well.

The purchase department use EPR system to make sure buying materials in time.

70-130 experienced workers can meet the customer request of batch production.

Quality department: 15 members quality control workers, testing the mould and parts by CMM and projector.

Domestic delivery: Logistics transportation

Delivery to overseas: FOB/CIF/DDU by sea shipping or air shipping Contact us if you need more details on Injection Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Mould、Washing Machine Drum Bottom Mold. If these products fail to match your need, please contact us and we would like to provide relevant information.

Mould Life: 50~100 shots

Material: ABS

Cavity: 1*1

Applicable range: Home appliance

Lead Time: 35-45 days

Hot runner: (according to the customer's request and product style)

Standard part: PUNCH, MISUMI

First trial equipment: 380T Injection Machine( moreover we also have 90-700T, 750-1300T Injection Machine. There are robots for each 90-380T Injection Machine to meet the customer's bulk production requirement.

Process step: Product design- CAE- 3D mold design- 2D drawing- CAM- Milling machine- Grinder- Drill- CNC- Wire cutting- EDM- Polishing- Trial assembly- Grind- Assemble- First trial

Our service: Product and mould design, Injection mould and parts machining.

Our main customer: Haier, Hisense, Midea, Siemens, SANYO, ELX, Toyota, Kia, Foton, GM Wuling, Great wall, Hyundai, Skyworth.

Overseas market: Japan, Korea, Thailand, Russia, Germany, England, Norway, Italy, USA, Spain, Turkey, Denmark, Brazil, Argentina, Egypt, South Africa, Iran, Pakistan, India.

Mould painting: According to Customer's request

Package: Wooden Case

The first trial success rate is above 95%

Quotation: Provide quotation in 24hours after received the customer's drawing.

The profile: 2D/3D drawing or samples

Manager: Concentrate on project tracking and after service

Engineer: 30-50 excellent engineers, have many years experience and English communicating well.

The purchase department use EPR system to make sure buying materials in time.

70-130 experienced workers can meet the customer request of batch production.

Quality department: 15 members quality control workers, testing the mould and parts by CMM and projector.

Domestic delivery: Logistics transportation

Delivery to overseas: FOB/CIF/DDU by sea shipping or air shipping Contact us if you need more details on Injection Mould. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Plastic Mould、Washing Machine Drum Bottom Mold. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Others Dies

Other Products

Hot Products

Hot Runner Mould&Injection Mould&Plastic Mould (C12)Vehicle Injection Mould / Auto Injection Molding (H70)Plastic Injection Mould/ Injection Plastic Mold (C8)Automatic Plastic Bottle Cap Molding MachtineMicrowave Oven Backpanel Parts&Microwave Oven Stamping Die (HRD-H39)Stamping Die/Metal Stampoing Tooling/Washing Machine Die (J03)Automatic Cap Compression Molding MachineSheet Metal Stamping/Progressive Stamping Metal Parts (J03)Pressing Automobile Metal Parts (HRD-H50)Stamping Die/Tooling/Metal Parts of Washing Machine (J03)Stamping Die/Toolingprogressive Tool (J03)Metal Deep Drawing Tool/ Drawn Metal Tooling of Washing Machine (J03)Stamping Die/Metal Stamping Tooling/Progressive Die (J03)Stamping Part (H03)Cap Automatic Progressive Molding MechanicalProgressive Stamping Tool for Motor Rotor Stator