Die Spotting Hydraulic Press for Automobile Mold 500T

- Packaging:

- WOODEN CASE

- Productivity:

- 300 Sets/Year

- Brand:

- ZHENGXI

- Transportation:

- Ocean

- Place of Origin:

- China

- Supply Ability:

- 300 Sets/Year

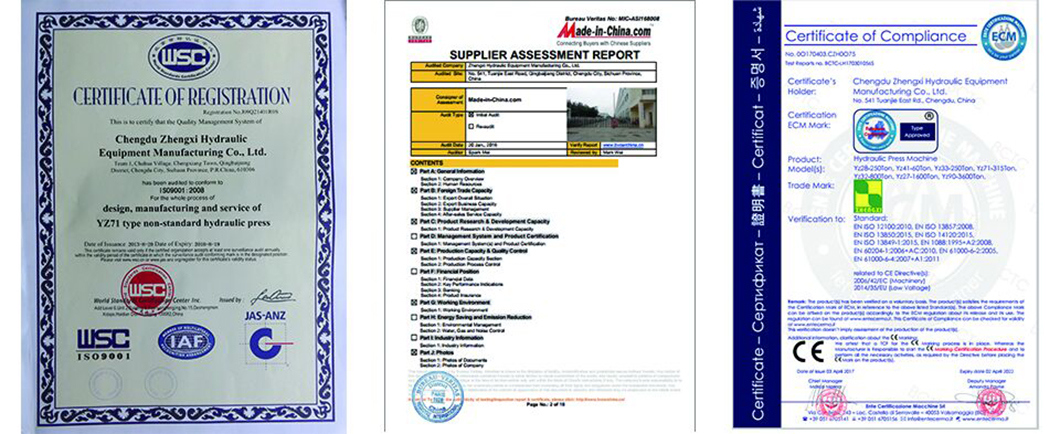

- Certificate:

- ISO9001, CE

- HS Code:

- 8462919000

- Port:

- CHONGQING,SHANGHAI

Basic Info

Model No.: Yz98

Product Description

When people talk about cars, the first thing that comes to mind is the body of the car. That is to say, the body is the identity assembly of the car. The body represents the image of the car. In the narrow sense, automotive molds are the general term for the molds that punch all the stampings on the car body. That is, "automobile body Stamping Die". For example, a top cover flange mold, a beam reinforcement plate press mold, and the like.

At present, with the increasingly fierce competition in the automotive industry, reducing costs, shortening the development cycle, and responding quickly to market changes have become the mainstream of automotive manufacturing technology development.

In order to become a leader in the global Automotive Parts manufacturing industry, it is necessary to fundamentally solve the problems of product quality and production management. Thoroughly eliminate the high rate of defective products due to the low personal quality of production workers and the ineffective management of production processes. The products that are shipped from the factory need a lot of rework. This requires a powerful set of information tools and scientific management processes to achieve. The above problems in the auto parts manufacturing industry are particularly prominent in automotive Stamping parts manufacturing enterprises. From the current problems in the industry, it is necessary to strengthen the internal quality management of stamping enterprises and establish a digital information quality control system to become a necessary means to improve product quality, reduce production costs and enhance the competitiveness of enterprises. The automobile stamping parts quality control system is a complete electronic information production quality control system with the purpose of deepening quality management, taking the software system as the core and relying on the hardware detection system.

Features

1.Hydraulic machine that used the hydrostatic pressure to process metal, plastic, rubber, wood, powder and other products .

2. It is commonly used in the pressing process and press forming process, such as: forging, stamping, cold extrusion, straightening, bending, flanging, sheet metal deep drawing, powder metallurgy, press-fit etc.

3.Significant technical and economic advantages in reducing weight, reducing the number of parts and the number of molds, improve the stiffness and strength, reduce production costs, etc.

Parameters

| Model | unit | Yz98-100A | Yz98-200A | Yz98-315A | Yz98-400A | |

| Capacity | KN | 1000 | 2000 | 3150 | 4000 | |

| Return force | KN | 500 | 700 | 1000 | 1200 | |

| Max.pressure of liquid | MPA | 25 | 25 | 25 | 25 | |

| Slider stroke | MM | 2300 | 2500 | 2500 | 2500 | |

| Open height | MM | 2500 | 2800 | 2800 | 2800 | |

| Max.capacity of turn over device | KN | 100 | 150 | 200 | 250 | |

| Max.turn over angle of turn over device | . | 180 | 180 | 180 | 180 | |

| Speed of slider | rapid down | MM/S | 60 | 80 | 100 | 100 |

| slow down | MM/S | 15 | 15 | 15 | 15 | |

| micro inching | MM/S | 0.5-2 | 0.5-2 | 0.5-2 | 0.5-2 | |

| slow rising | MM/S | 15 | 15 | 15 | 15 | |

| rapid rising | MM/S | 80 | 80 | 80 | 80 | |

| Worktable dimension | L-R | MM | 4000 | 4600 | 4600 | 5000 |

| F-B | MM | 2200 | 2500 | 2500 | 3000 | |

| Moving table stroke | MM | 2400 | 5200 | 5200 | 6200 | |

| Total power | KW | 30 | 44 | 52 | | |

Factory

Packaging and delivery

Certificate

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Chengdu City ,Sichuan Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : H Type Hydraulic Press > Die Spotting Hydraulic Press